Before, most bus duct manufacturers were influenced by the old design ideas and manufacturing specifications, and the selection of conductors in the duct was mainly copper. Because the price of copper has risen a lot in recent years, the manufacturing cost has suddenly increased greatly, which undoubtedly has a great impact on the market expansion of manufacturers. Combined with the rational allocation of market resources and price factors, the conductor of domestic bus duct products will be transferred from copper bus material to aluminum bus material, and the future development trend of products has been obvious.

The specific comparison between aluminum and copper conductors of bus duct is as follows:

(1) Comparison of, copper and aluminum conductor metal materials:

The density of copper is 8.9g/cm3 and that of aluminum is 2.7g/cm3;

The conductivity of copper is second only to silver. The IACS values of 99.996% high-purity aluminum and 99.5% industrial pure aluminum are 64.94% and 59%, that is, the conductivity of copper is about 35% ~ 40% higher than that of aluminum;

(2) The chemical stability of copper in the atmosphere is better, and aluminum is more active, but adding trace alloying elements can improve its chemical stability. From the point of view, the strength and hardness of copper are better, but that of pure aluminum is worse. However, aluminum alloy can obtain higher strength and hardness after heat treatment. Due to its light weight, its strength is much greater than that of copper;

(3) In nature, copper resources are relatively limited, so the price is relatively high. Aluminum resources are relatively rich and the price is relatively cheap:

It can be seen from the general economic analysis of copper conductor bus duct and aluminum conductor bus duct with equivalent conductive section. Only from the analysis of conductor material cost of bus duct, the former is only about 1 / 5 of the latter compared with copper conductor bus duct.

Due to the special manufacturability of aluminum conductor bus duct in the manufacturing process, the manufacturing cost is relatively high. The analysis shows that the comparison between the two is about 2.5:1.

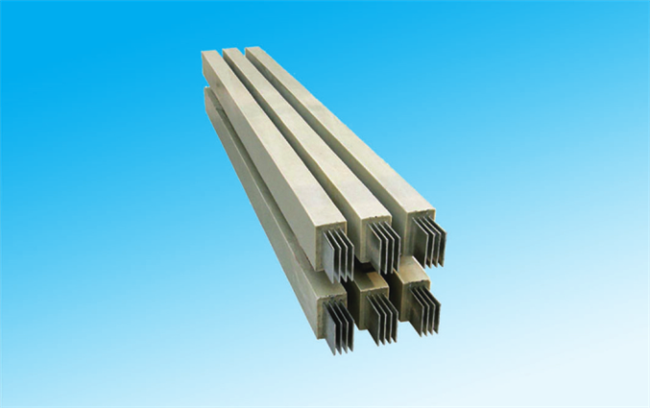

(4) Aluminum bus conductor bus duct has been widely used in some developed countries, and the manufacturing technology and process have gradually matured:

In recent years, some domestic bus manufacturers have also provided high-quality aluminum conductor bus duct, which has been affirmed and praised by users and design units in practical engineering application, showing the unique advantages of cast bus duct.

中文(简体)

中文(简体)