Since the section of bus duct is not specified in the national standard, the section of bus duct marked with the same rated current of the same model is often different from that of different manufacturers. There are several reasons for this

(1) The cross section of the conventional sample is different from that of the actual product. Previous routine test reports did not indicate the section of the tested bus duct. Since reducing the section of bus duct can reduce the cost and generate routine test report, large section bus duct is used as small section bus duct for routine test.

(2) Product parts and specifications are inconsistent. For the sample without marked bus duct section, the designer shall pay attention to prevent the manufacturer from counterfeiting.

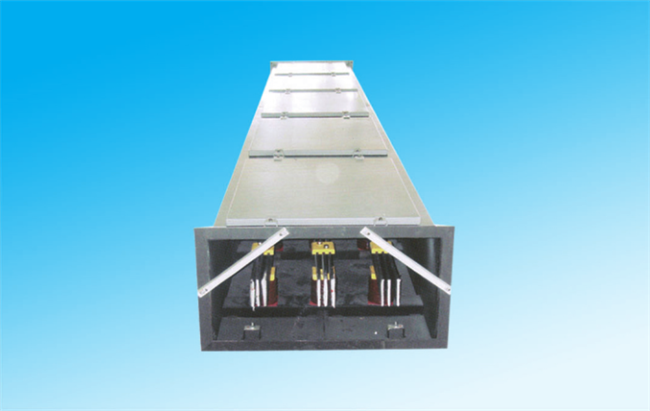

Bus duct is a conductor connecting branch circuits of electrical equipment. It is the carrier for collecting and distributing power, also known as bus duct. Traditionally, the conductor of the current carrying branch in each distribution unit is usually called bus duct. The function of bus duct is to collect, distribute and transmit electric energy. During the operation of bus duct, a large amount of electric energy passes through. When the bus duct is short circuited, it will produce great thermal effect and electric effect. Therefore, it is very necessary to reasonably select the bus duct material, section shape and section area to meet the requirements of safe and economic operation.

The selection and application of bus duct under different environmental conditions shall consider the selection of bus duct of different types and materials. In addition, for various bus ducts, the bus duct section shall be selected according to the long-term working current. The short-time thermal stability and dynamic stability of bus duct are verified under the condition of short-circuit current. Due to the resistance of wires and the action of AC ammeter when multiple wires are close, heat will be generated when the bus duct passes through the current. The allowable heating temperature for long-term operation of copper and aluminum bare bus duct is 70 ℃, but when there is a reliable tin coating (such as ultrasonic tin plating) on the contact surface, the allowable temperature is increased to 85 ℃. Limited by the allowable temperature of continuous heating, the long-term allowable current values of bus duct with different materials and sections are given. When selecting the section of bus duct, the actual long-term working current of bus duct (including overload exceeding half an hour) shall be less than the long-term allowable current of bus duct of the selected section. When the average load of the year is large and the conductor and bus duct are large (such as the bus duct of outdoor distribution equipment), the bus duct is usually selected according to the economic current density method. Economic current density refers to the current flowing through the unit cross-sectional area of bus duct under the condition of considering bus duct loss, annual maintenance cost and depreciation cost of bus duct and auxiliary equipment. The section of bus duct can be obtained by dividing the economic current density by the long-term non overload working current. The section of bus duct selected by economic current density method is generally larger than that selected by long-term working current method.

中文(简体)

中文(简体)